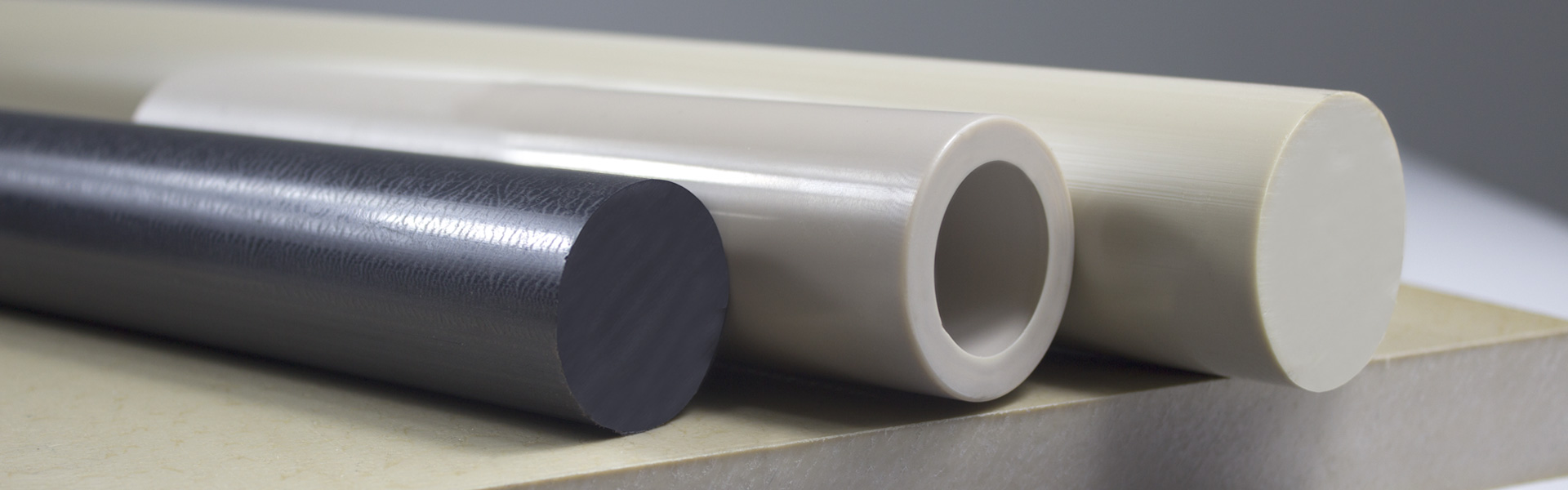

PEEK sheets have been widely used in aerospace, medical, semiconductor, pharmaceutical and food processing industries, such as gas separator components on satellites, heat exchanger scrapers; Because of its superior friction performance, it has become an ideal material in friction applications, such as sleeve bearings, sliding bearings, valve seats, sealing rings, pump wear rings, etc. Parts for various production lines, parts for semiconductor liquid crystal manufacturing devices, parts for inspection devices, jigs for manufacturing, atomic energy related parts, electronic components, various precision machine parts, food processing line related parts, chemical mechanical equipment related parts, welding machine related parts, gilding processing machine related parts, metal surface treatment related parts, Important tips, such as thermal insulation components, specifications and dimensions: 1-100MM * 610/1000MM * 1000MM. When the temperature is above 150 ℃ (higher than the glass phase transition temperature), the mechanical properties of all PEEK grade plastics rapidly decline, while the linear thermal expansion coefficient rapidly increases. If the temperature exceeds 150 ℃, if it meets a large standard, PAI can be selected to manufacture high temperature resistant parts.