The function of PEEK sheet machined parts is remarkable because its outstanding strength and resistance, extensive operating temperature scale, high chemical corrosion resistance, wear resistance and ease of processing are combined. Therefore, PEEK sheet is used in automobile manufacturing industry.

The information used for most injection molded cages is PA66 (polyamide 6,6). The strength, elasticity and other mechanical functions of polymerization materials are related to temperature and will change under operating conditions, which is called aging. During the aging process, the temperature, time and medium (lubricant) that the polymer is exposed to are all crucial factors. On the surface, the life of the cage is shortened with the increase of temperature and the corrosivity of lubricant. Due to the strong corrosivity of some media, the cage made of glass fiber reinforced polyamide 6,6 cannot be used at the operating temperature above+70 ° C. Typical example is ammonia used as refrigerant in compressor.

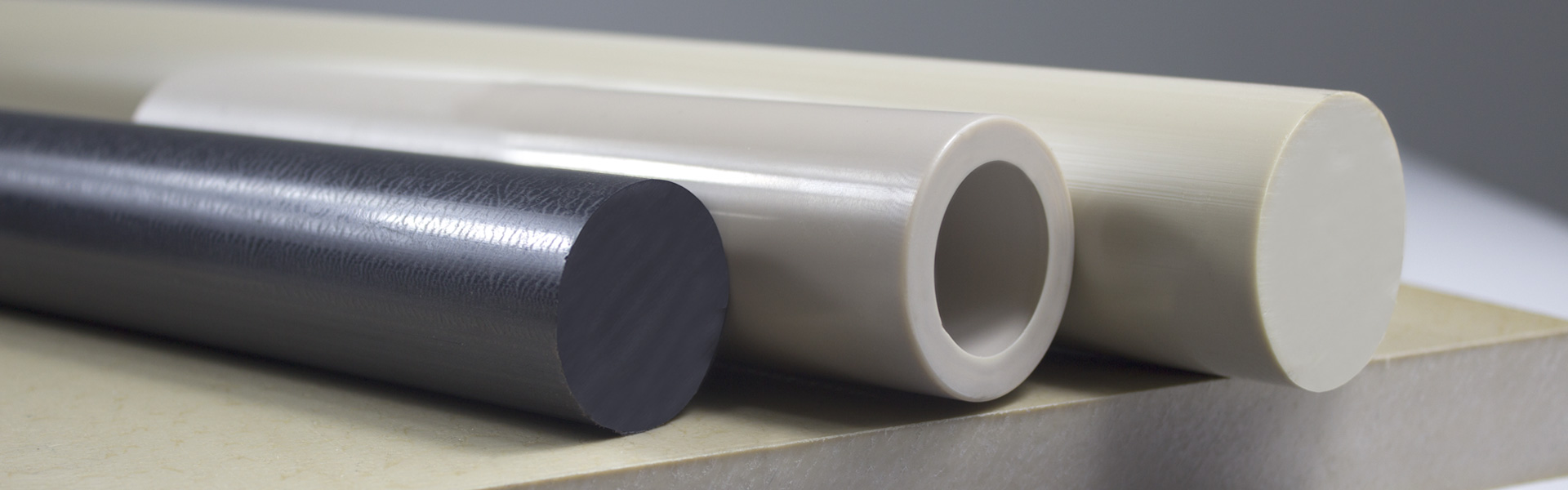

PEEK sheet processing parts: The original materials used to make the bearing parts determine the function and reliability of the rolling bearing to a large extent. In order to satisfy the use needs of the car category, engineers began to use high function data such as PEEK machining parts aggregate data in the planning of deep groove ball bearings.

The cage is not only affected by mechanical stresses such as friction, tension and inertia force, but also needs to withstand the chemical action of some lubricants, lubricating additives or their aging products, organic solvents or coolants. The relative impact of such matters may be affected by other operating parameters, including high temperature, impact load, vibration or the combination of such elements and other conditions. As a result, planning and information play an important role in the function of cage and the operation reliability of bearing itself. This is why engineers develop cage types based on PEEK workpiece aggregation data and plan for the requirements of the car industry.