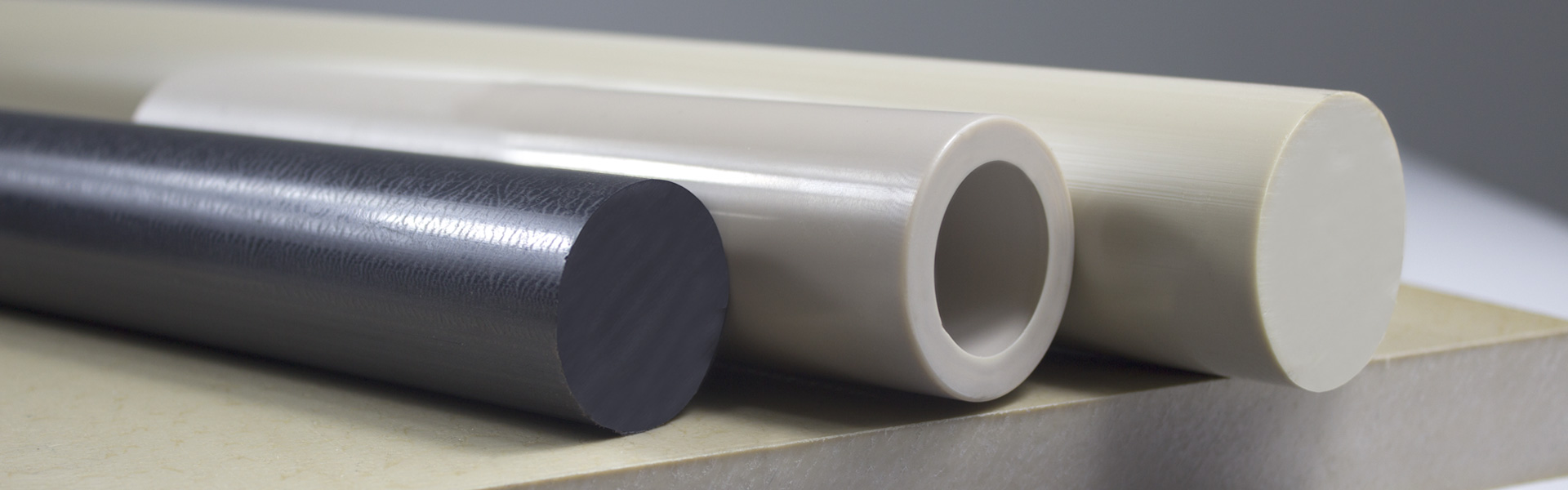

It is widely used. It is a good material to replace steel, iron, copper and other metals with plastics. It is an important engineering plastic; Cast nylon is widely used to replace the wear-resistant parts of mechanical equipment and copper and alloy as wear-resistant parts of equipment. It is suitable for making wear-resistant parts, transmission structure parts, household electrical appliance parts, automobile manufacturing parts, screw rod prevention mechanical parts, chemical machinery parts and chemical equipment. Such as turbine, gear, bearing, impeller, crank, instrument panel, drive shaft, valve, blade, screw rod, high-pressure washer, screw, nut, seal ring, shuttle, sleeve, shaft sleeve connector, etc.

Quality identification:

What are the properties of nylon board to be considered as good quality? Henan Airlines will explain for you. The appearance of nylon is milky white to light yellow, free of mechanical impurities and uniform particles with surface moisture, and the particle size is more than 40 particles/g, with the content of small black spots no more than 2%. It is characterized by toughness, shock resistance, high mechanical strength and heat resistance, good impact strength, high melting point, good molding and processing performance, high water absorption, saturated water absorption of about 11%, and easy to melt in sulfuric phenols or formic acid, The low temperature embrittlement temperature is 20 ℃ - 30 ℃ below zero.

Nylon plate transparent PA:

It has good tensile strength, impact strength, rigidity, abrasion resistance, chemical resistance, surface hardness and other properties. It has high light transmittance, which is similar to optical glass. The processing temperature is 300-315 ℃. During molding and processing, the barrel temperature needs to be strictly controlled. If the melt temperature is too high, the product will change color due to degradation, and if the temperature is too low, the transparency of the product will be affected due to poor plasticization. The mold temperature should be kept as low as possible. High mold temperature will reduce the transparency of products due to crystallization.