Each material has its own characteristics and cannot be completely replaced, but partial replacement is still possible.

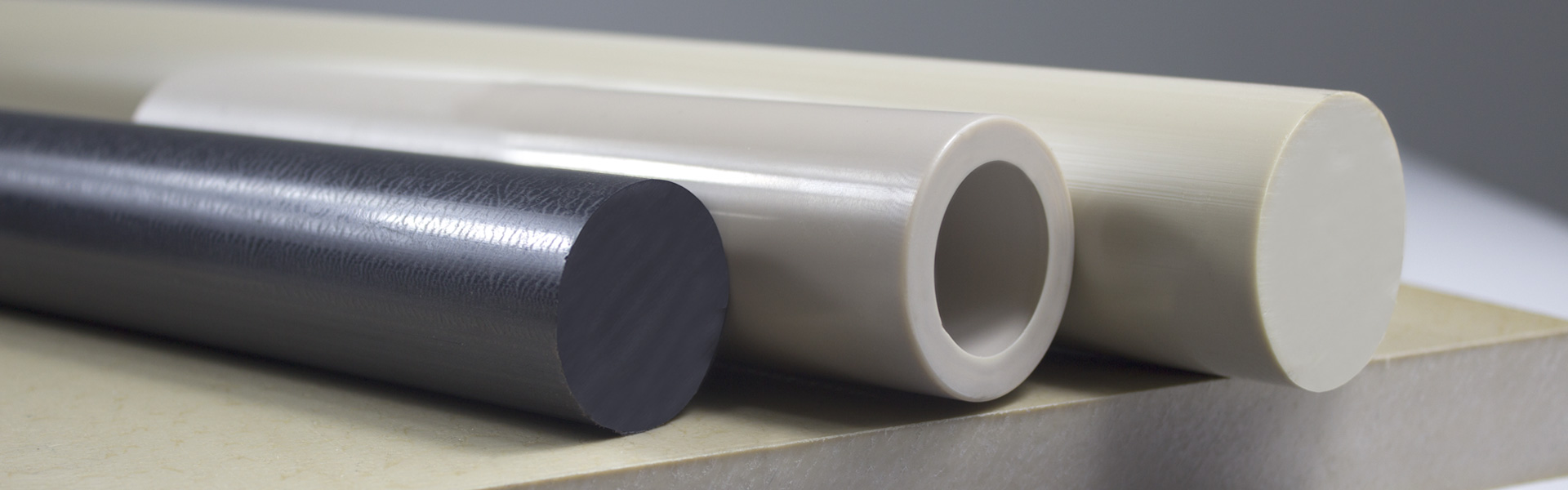

PEEK material is a kind of special engineering plastics, which has the characteristics of high strength, high temperature resistance, chemical resistance, wear resistance, etc. It is widely used in aerospace, petrochemical, electronic and electrical appliances, medical, auto parts and other fields. There are many materials that can replace one aspect of its characteristics.

High temperature resistance: PI greatly exceeds PEEK in high temperature.

High strength: PPS, PI, PAI and other materials can replace PEEK.

Chemical resistance: Fluorine plastics surpass PEEK in this respect.

Wear resistance: PI, fluoroplastic, ultra-high molecular weight PE can be replaced.

The selection of appropriate materials depends on the use environment of the product. Jingchenmai has been committed to the field of special plastics for many years, and can carry out a variety of molding processes such as extrusion molding, injection molding, compression molding, and machining molding. According to the customer's drawings and sample requirements, develop and manufacture injection and molding molds, and customize various specifications and widely used PEEK parts and finished products.