Plastic PEEK is a special engineering plastic with excellent properties such as high temperature resistance, self-lubricating, easy processing and high mechanical strength. It can be manufactured into various mechanical parts, such as automobile gears, oil screens, shift starting discs; Aircraft engine parts, automatic washing machine runner, medical equipment parts, etc. Plastic PEEK is a kind of special engineering plastics. It is a macromolecular polymer composed of aryl, ketone and ether bonds. It has many characteristics such as high temperature resistance, strong flame retardancy and excellent chemical stability. It is often used in engineering machinery, aerospace products.

Performance advantages of PEEK plastic: strong heat resistance and high temperature resistance. The positive high temperature resistance of PEEK plastic reaches 260 ℃, and the thermal deformation temperature reaches 160 ℃. If 30% glass fiber is added for modification, the thermal deformation temperature can be increased to 280-300 ℃. The electrochemical performance is excellent. Even in the high frequency range, PEEK plastic can still maintain a small dielectric index and dielectric loss. Data research shows that under the environment of 10HZ, its dielectric constant is only 3.2, and the dielectric loss is only 0.02. It has excellent chemical stability. It is resistant to acid and alkali. It is resistant to almost any chemical reagent except concentrated sulfuric acid. It also has good stability at high temperature. It has excellent hydrolysis resistance and can be used for a long time even in the steam environment of 200-250 ℃. In addition to the above advantages, PEEK plastic also has excellent flame retardancy, melt fluidity, thermal stability, corrosivity, high strength and easy molding and processing.

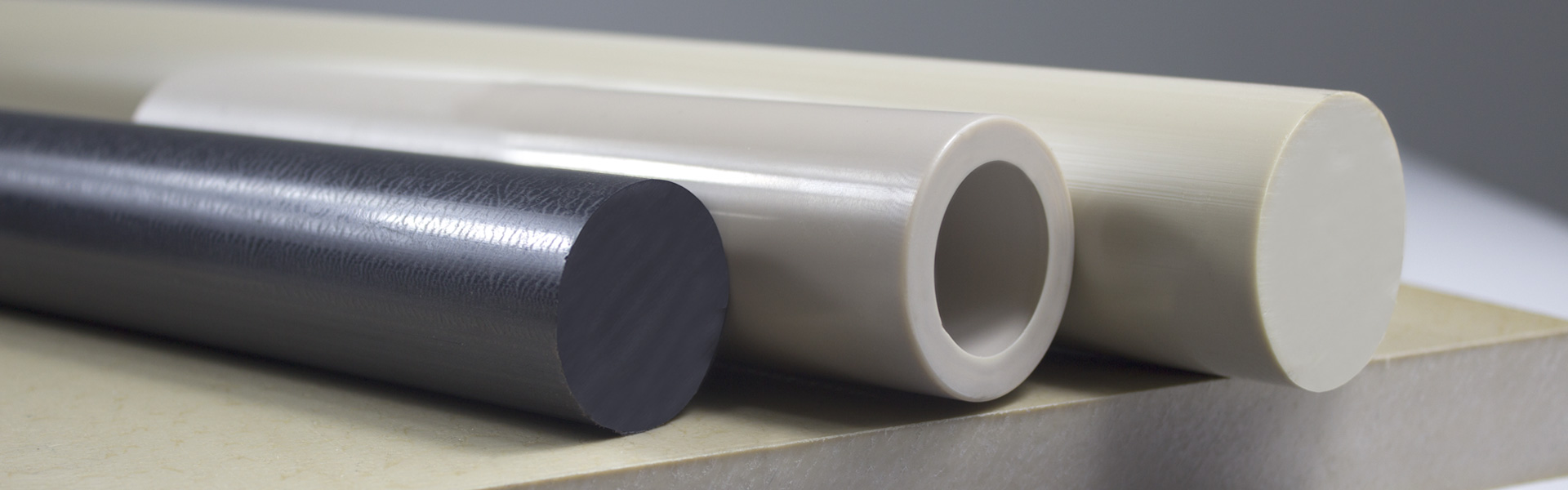

Application of PEEK Plastics PEEK plastics are widely used in chemical industry, electronic equipment, automobile industry, aerospace and other fields because of their outstanding high temperature resistance, heat resistance, strong height and formed processability. Here we list some common plastic products, such as PEEK seals, PEEK plates, PEEK bars, PEEK tubes, etc. Development of PEEK Plastics Although the performance of PEEK plastics is good, it is limited by the impact of polymerization monomer, production capacity and technology. The development of PEEK plastics has been at a low ebb. At present, the price of raw materials is high, and the scope of market application is limited. It is expected that the application of PEEK will be greatly improved with the development of technology in the future.