PEEK has the characteristics of high temperature resistance, radiation resistance, corrosion resistance, good dimensional stability, excellent electrical performance, etc., and also has excellent processing performance. It is easy for injection molding, extrusion molding and cutting processing. It is one of the special engineering plastics with excellent comprehensive performance. The mechanical properties, heat resistance and friction resistance of PEEK can be further enhanced by modifying PEEK with fiber reinforcement, inorganic filler filling and blending of organic materials to obtain PEEK plastic alloy or PEEK composite with better performance. At the same time, because the price of PEEK material is higher than that of ordinary engineering plastics, blending with other materials can not only endow the material with more excellent properties, It can also improve the cost performance of materials, reduce the cost of materials, and expand the scope of use.

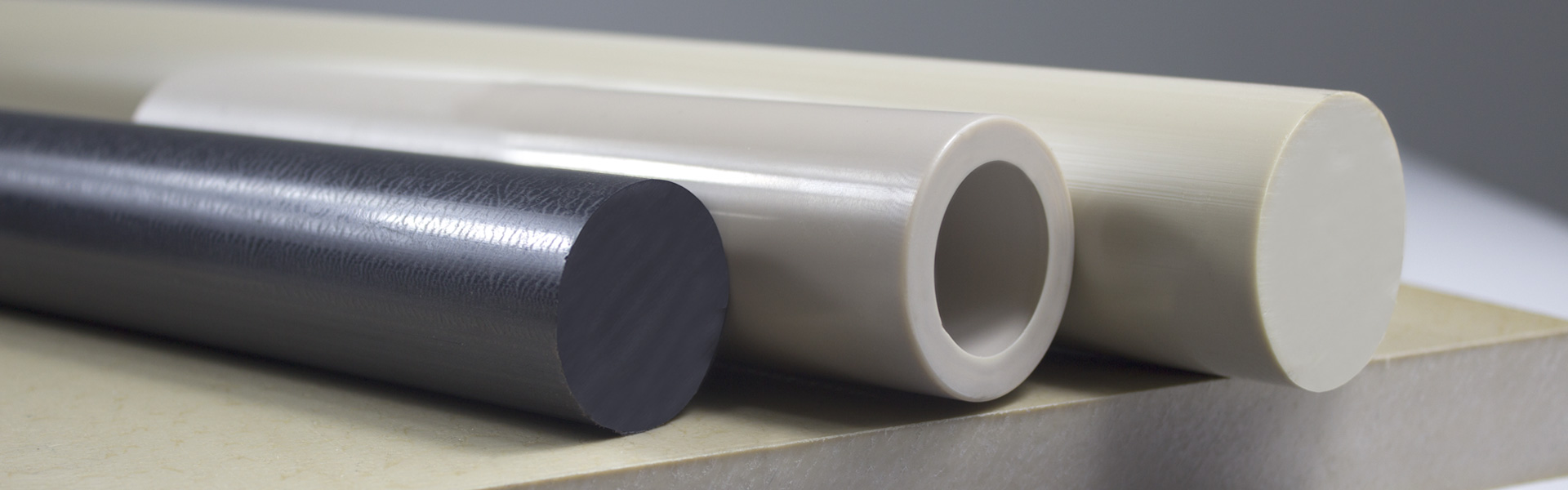

The color of pure PEEK material is generally light yellow, the modified (carbon fiber and graphite added) PEEK material is generally black, and the PEEK with glass fiber added is generally coffee color.

Characteristics of different grades of PEEK materials

Pure PEEK material has good toughness and impact resistance.

With carbon fiber PEEK material, it has good friction and mechanical properties, so it is very suitable for use in the field of wear resistance.

With glass fiber PEEK material, it has stronger rigidity, creep resistance, better dimensional stability, and is more suitable for manufacturing some structural parts